| Steel Industry |

Case Study: Direct application on hot steel slab using robotic labeler system

| Object | Steel Slab |

| Application Temperature | 800℃ |

| Products | HEATPROOF HP-700T |

Customer’s Request

Identify hot steel slabs using HEATPROOF label. Verify identity of slab before entry into rolling mill.

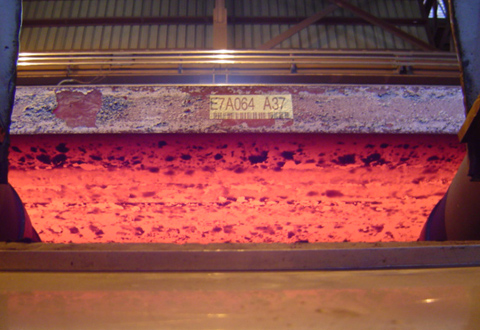

Initial Process Management

Visual inspection of spray marking

Spray marking at 800℃

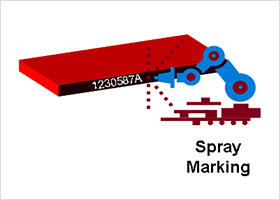

Shipping label is applied after slab has cooled

Label application at stock yard after slab has cooled

Process Issues

- Spray marking information drops off with scale.

- Incorrect label is applied after slab has cooled, causing misidentified products.

- Automated verification of spray marked slab identity is very difficult. Human reading errors cause issues in downstream processes.

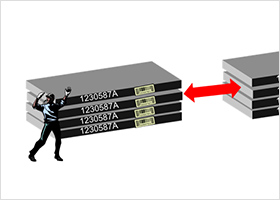

HEATPROOF Solution

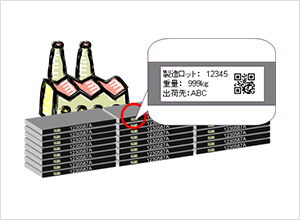

| 1 | Barcodes are used for accurate product identification. |

| 2 | HEATPROOF labels are applied early in the production process, eliminating costly identification errors. |

| 3 | Products in inventory can be identified with scanners or imaging devices. |

Eliminate the need to re-identify products in inventory.

Verify identity prior to shipping. Visual verification leads to errors. Use barcode scanning systems to ensure correct product is shipped to your customer

| 4 | Eliminate misidentified product. Improve shipping accuracy. Streamline inventory reconciliation. |