| Steel Industry |

Case Study: Direct application on hot steel coil

using robotic labeler system

| Object | Steel Hot Coil |

| Application Temperature | 550℃ |

| Products | HEATPROOF HP-600 |

Customer’s request

- Identify and barcode hot coils soon after rolling

- Include coil characteristics and shipping information

- Eliminate coil identification and shipping errors

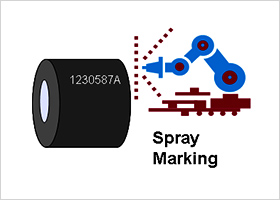

Initial Process Management

Visual inspection of Spray marking

Spray marking at 550℃

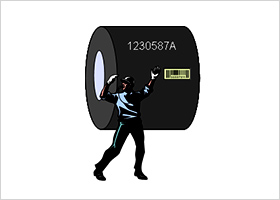

Shipping label is applied after coil has cooled

Coil number is visually checked in coil inventory yard. Label is printed and applied on cool coil.

Process Issues

- Hot coil management using barcode identification is difficult

- Incorrect label is applied after coil has cooled, causing misidentified products.

- Coil must be re-identified down stream. This is not efficient

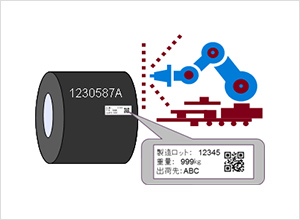

HEATPROOF Solution

| 1 | Improvement of coil identification using barcodes and scanners. |

| 2 | Elimination of inefficient processes such as coil re-identification. |

| 3 | Reduce coil marking costs. Streamline inventory reconciliation. |

HEATPROOF label applied in process at 550℃

| 4 | Eliminate the need to re-identify coils after cooling |

Spray marked coils must be re-labelled after cooling

HEATPROOF labels are applied as soon as the coil is produced

Improved shipping accuracy and lead time