Features of HEATPROOF

Labels & Tags

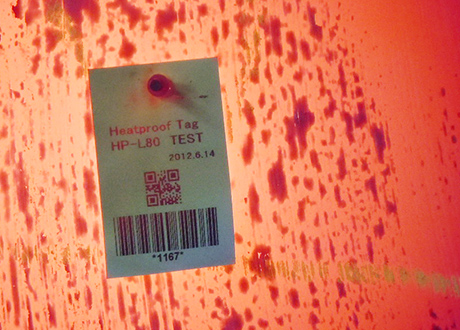

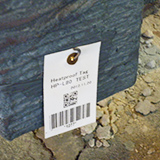

Product tracking and identification have become critically important to avoid costly mistakes from misidentified materials and incorrectly shipped product. Quality control relies on accurate product identification and verification procedures. These procedures must be followed even through high temperature and harsh environment processes. HEATPROOF labels and tags can provide product traceability and identification at temperatures up to 1200°C.

-

YS Tech’s proprietary technology allows labels to be applied to objects at temperatures up to 1000℃. Labels can be applied manually or with robotic systems.

-

HEATPROOF Labels & Tags can withstand heat treatment processes with temperatures up to 1200 ℃ in various atmospheres.

-

Barcodes can easily be created and printed on a standard, commercially available, thermal transfer printer.

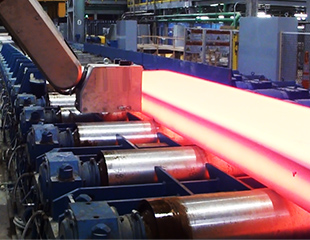

Direct Hot Application

Direct Hot Application

Using Pressure Sensitive Labels

Barcode labels can be applied directly onto hot surfaces at temperatures up to 1000 °C using manual applicator devices or fully automated labelling systems. Applying barcodes early in the manufacturing process can improve product tracking and reduce labor costs.

Direct Hot Application

Using Non-Adhesive Tags

Tags can be attached to hot surfaces up to 1200 °C. Attachment methods include nailing, spot welding, stud welding, or wire ties.

Heat Treatment Process Management

Heat Treatment - Labels

Pressure Sensitive at Ambient Temperature

For processes such as homogenizing, annealing, or reheating, labels can be applied at room temperature. Barcodes are scanned as they enter and exit the furnace for accurate product tracking.

Heat Treatment - Tags

Non-Adhesive for Ambient Application

Attach tags using a variety of methods including nailing, spot welding, stud welding, or wire ties. Tags are resistant to temperatures up to 1200°C, and offer excellent readability and reliability for product tracking.

On-Site Printing

HEATPROOF Label & Tag Printing

Barcodes, text, and other on-site information can be printed on heat resistant labels & tags, using a standard thermal transfer printer.